Regenerative medicine is an exciting and rapidly developing field that involves replacing or regenerating human tissues to re-establish their normal function. In the lab, scientists are trying to create and improve biomaterials to use for tissue repair.

For instance, vocal cords can be severely damaged in patients who suffer from laryngeal cancer. For these patients, as well as others with vocal cord damage, one promising therapy involves injecting a biomaterial into the affected folds to regenerate them. However, existing biomaterials for this procedure have significant limitations.

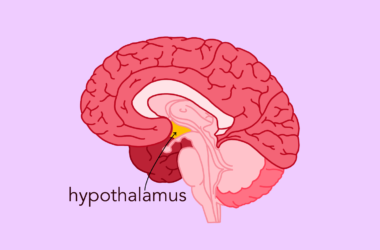

First, the implant should allow the cells of the damaged vocal cord to exchange nutrients and waste with their environment and to migrate into the implant for proper incorporation. Therefore, the material needs to be porous. Because a large invasive surgery to implant the biomaterial into the vocal cords could be detrimental to the patient, it needs to be injectable. Finally, given that the vocal cords are extremely dynamic due to their high vibrational frequency, the biomaterial needs to be resistant to high levels of mechanical stress.

With existing biomaterials for such procedures failing to exhibit these three crucial characteristics, patients often suffer the repercussions of unsuccessful implants and frequent re-injections.

Recently, a team of scientists in the Department of Mechanical Engineering at McGill created a highly effective biomaterial made of hydrogel that respects all three requirements. Hydrogel is a material made up of at least 10 per cent water, as well as large biomolecules called polymers. Its composition resembles the extracellular matrix found between the cells in our bodies, making it very biocompatible.

Jianyu Li, an assistant professor in the Department of Mechanical Engineering at McGill and the Canada Research Chair in Biomaterials and Musculoskeletal Health who co-led the study, explained the drawbacks of current hydrogel materials.

“The problem with injecting hydrogel is that it becomes condensed when it goes through the needle and therefore any pre-formed pores will collapse,” Li said in an interview with The McGill Tribune. “We designed a hydrogel in which the pores form spontaneously post-injection.”

To acquire this special property, they used an ingredient they kept secret until the publication of their paper in Advanced Science in November 2021. It’s called chitosan, a natural polymer found in the shells of crabs, shrimps, and lobsters that is able to stay liquid in acidic solutions instead of solidifying right away. Once it is injected into the human body—which has a neutral pH—phase separation occurs and the material solidifies, creating a rigid matrix with pores.

“In the previous materials, it would take a very long time for the cells to migrate, as the pores weren’t large enough,” said Guangyu Bao, a Ph.D. candidate in mechanical engineering who co-led the study, in an interview with the Tribune. “The material would need to be degraded for the cells to infiltrate the implant. Our material has pores big enough to allow the nutrients to diffuse easily, and the cells to migrate into the hydrogel, effectively fusing it with the existing vocal cord.”

This biomaterial could also be used to repair other mechanically dynamic tissues such as the heart, the lungs, and musculoskeletal tissue, and even steady tissue, such as that of the kidney.

“No matter what kind of tissue you want to repair, you always need the material to be porous for the nutrients to be delivered and for the cells to survive, and you always want this minimally invasive approach, so, injectability,” Li said.

The team’s hydrogel can also be used for purposes outside of regenerative medicine, such as in the field of microfluidics. Microfluidic devices can be thought of as small chips with circuits of fluids. Their applications are vast: For example, they can be used to model biological systems. According to Bao, scientists are even using microfluidics to study how drug treatments against COVID-19 would work in the lungs.

“It’s mostly being done in 2D [on a chip],” Bao said. “With our biomaterial, we can form a 3D environment [with the fluid flowing throughout the porous hydrogel], which gives a better mimicry of the human tissue. It could possibly change the way people do microfluidics.”