Sutures, the threads designed to close wounds and promote healing, have been used for thousands of years, having originated in ancient Egypt. Since their invention, physicians and scientists have experimented with a wide array of materials, from hemp and cotton to more modern synthetic fibres. New techniques have been developed that improve patient outcomes, reducing infection risks, facilitating the natural healing process, and lessening the appearance of scars.

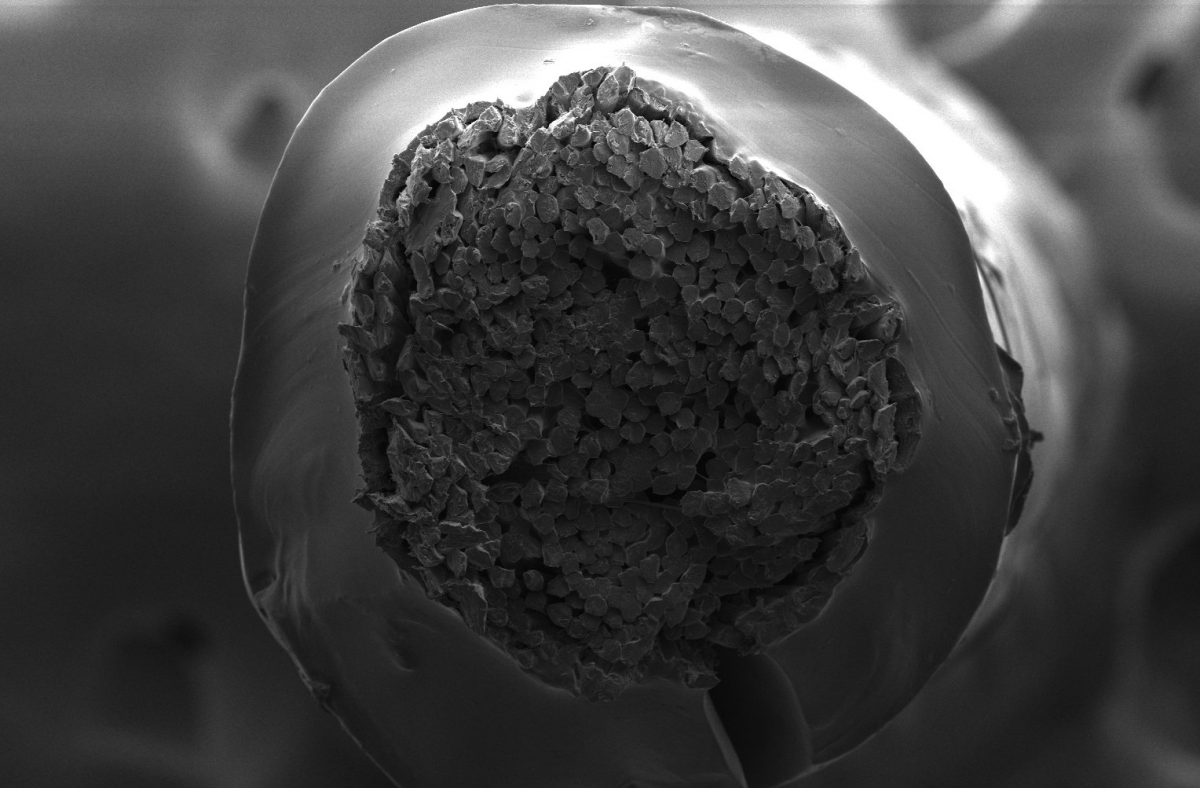

The current standard of care for suturing is far from perfect, however; suture materials can slice and damage already fragile tissues or cause inflammation by rubbing against adjacent tissues. This damage occurs because the materials used are dry and rigid, having been developed to bear tension as the wounds close. The rough fibres of sutures also conflict with the soft tissues they interface with, sometimes leading to postoperative complications.

Zhenwei Ma, a PhD student supervised by Dr. Jianyu Li, assistant professor of McGill’s Department of Mechanical Engineering, looked to the human body for solutions to this problem. Ma led a team of engineers, clinicians, and pathologists to develop the tough gel sheathed (TGS) suture—a new suture technology inspired by the human tendon.

Ma hopes the bio-inspired design could offer a solution to the drawbacks that traditional sutures present. Like the human endotenon sheath, the next-generation TGS suture is designed to bear tension. TGS’ hydrogel surface is also less stiff than that of sutures currently being used, reducing friction with surrounding tissues.

“For our TGS surgical sutures, our design is inspired by […] the endotenon sheath, which is both tough and strong due to its double-network structure,” Ma wrote in an email to The McGill Tribune “It binds collagen fibres together while its elastin network strengthens it. This clever design found in nature inspires us to develop a tough double-network hydrogel sheath for surgical sutures with advanced wound-management functions.”

The TGS sutures can be used to deliver medication directly to the wound and monitor healing with near-infrared imaging. The team was inspired by limitations of current medical technology and Ma hopes other researchers will leverage this design to tackle different clinical challenges.

“We [were] inspired by the limitations of existing medical devices and biomaterials used in operating rooms and clinics,” Ma wrote. “Building upon this platform technology, we are planning to extend the surface functionalization strategy to other fibre-based biomedical devices. Hopefully, this technology will also inspire and be leveraged by other researchers around the world to functionalize their biomaterials-of-interest.”

Although the team is currently working closely with clinicians in local McGill affiliated hospitals in Montreal, they believe this technology can be adapted to different biomaterials to meet distinct needs around the world, such as combatting rare diseases. Ma also hopes that translational clinical research will spark conversations between professionals from different disciplines and lead to out-of-the-box thinking with the potential to revolutionize treatment strategies.

Nevertheless, bench-top (lab-based) research faces a unique set of challenges before it can be translated into bedside use—from testing efficacy in patients to regulatory approval and product manufacturing.

“As you can imagine, it would literally take a village and years’ efforts to make it happen,” Ma wrote.

With this new technology, innovation at the intersection of human anatomy and mechanical engineering is resulting in the emergence of translational clinical research as a viable strategy to meet patient needs.

A previous version of this article incorrectly stated that TGS sutures would allow patients to move freely without disrupting their stitches. In fact, sufficient testing has not been performed to confirm this. The Tribune regrets the error.